Shanghai Fochier International Trade Co., Ltd.

Customize Size Cast Acrylic Sheet

Customize Size Cast Acrylic Sheet

Couldn't load pickup availability

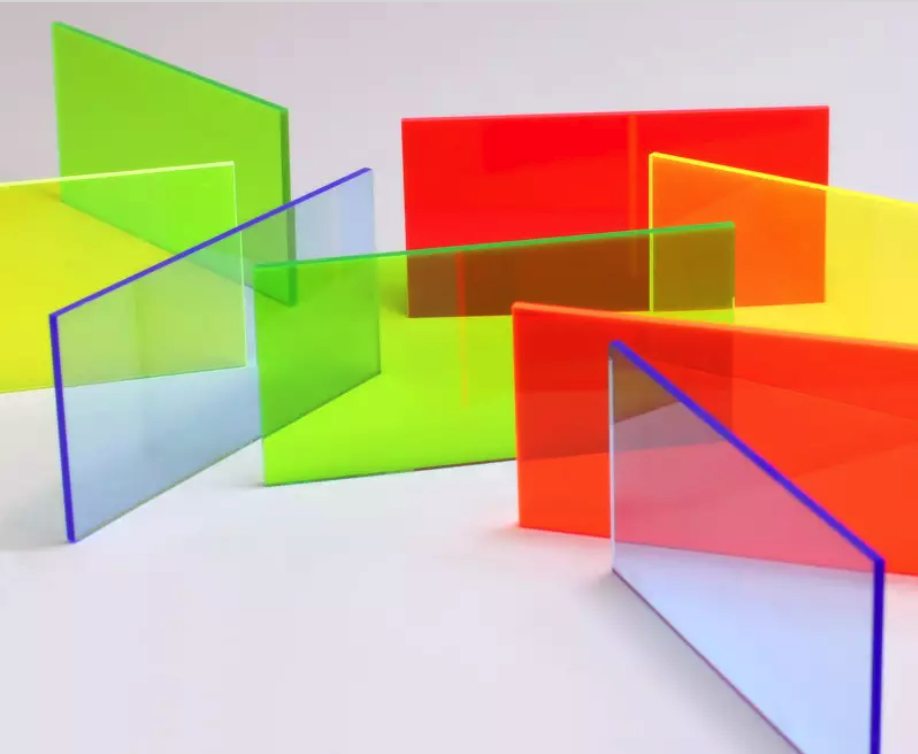

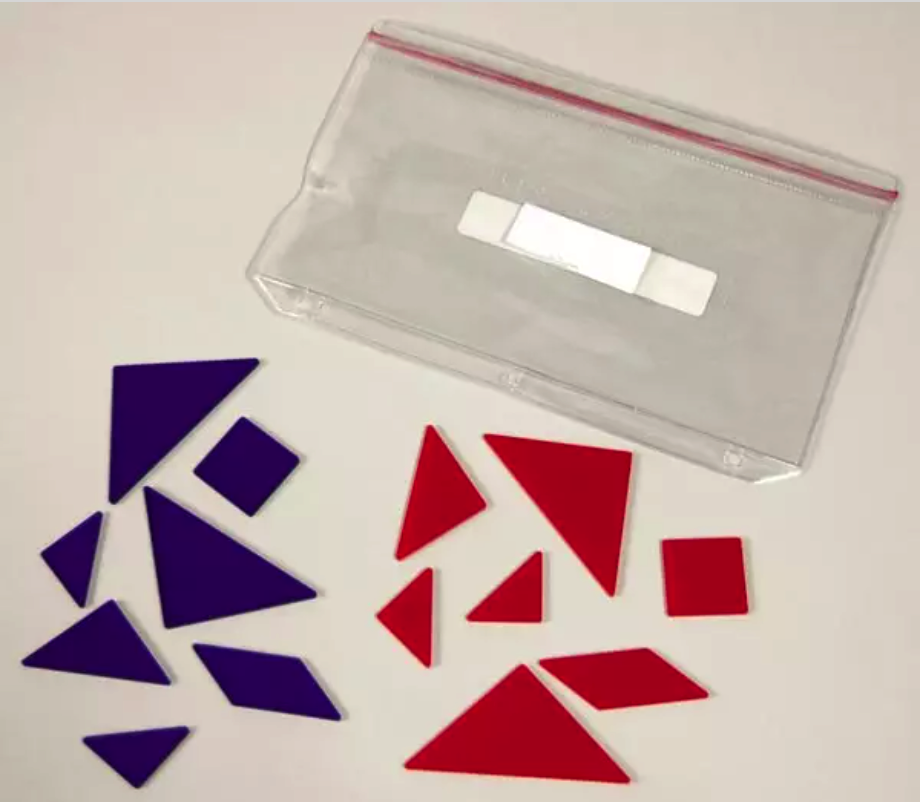

Acrylic sheet another name is PMMA Sheet or Plexiglass Sheet, we provide cut-to-size service. We provide laser cutting, processing, diamond polish and printing on acrylic sheet service. We also provide different colors acrylic sheets, such as clear acrylic sheet, black acrylic sheet, red acrylic sheet.The thickness we can provide is 1/2 acrylic sheet, 1/4 acrylic sheet, 1MM acrylic sheet, 2MM acrylic sheet, 3MM acrylic sheet, 4MM acrylic sheet, 5MM acrylic sheet and so on.

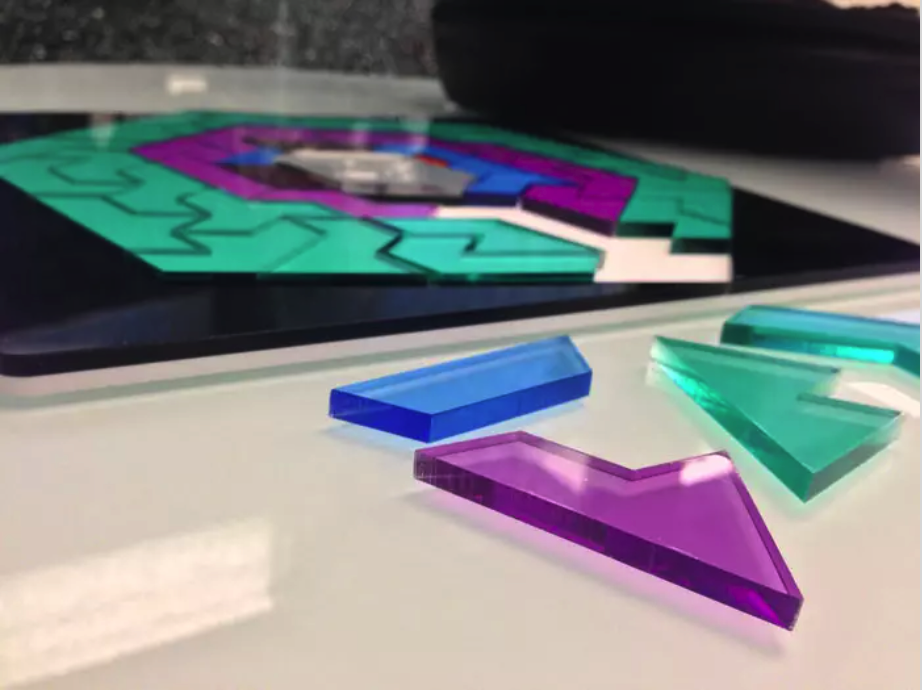

Acrylic Processing Service

Cut to size service

Bend acrylic sheet by acrylic heat bending machine

Use transparent acrylic sheet to make acrylic display boxes

Painting and Printing on acrylic sheet

Use laser cutting machine to cut acrylic sheet, provide acrylic cutting service

Engrave on opaque acrylic sheet

Provide your solution best way to cut acrylic sheet

What is the type of acrylic sheet?

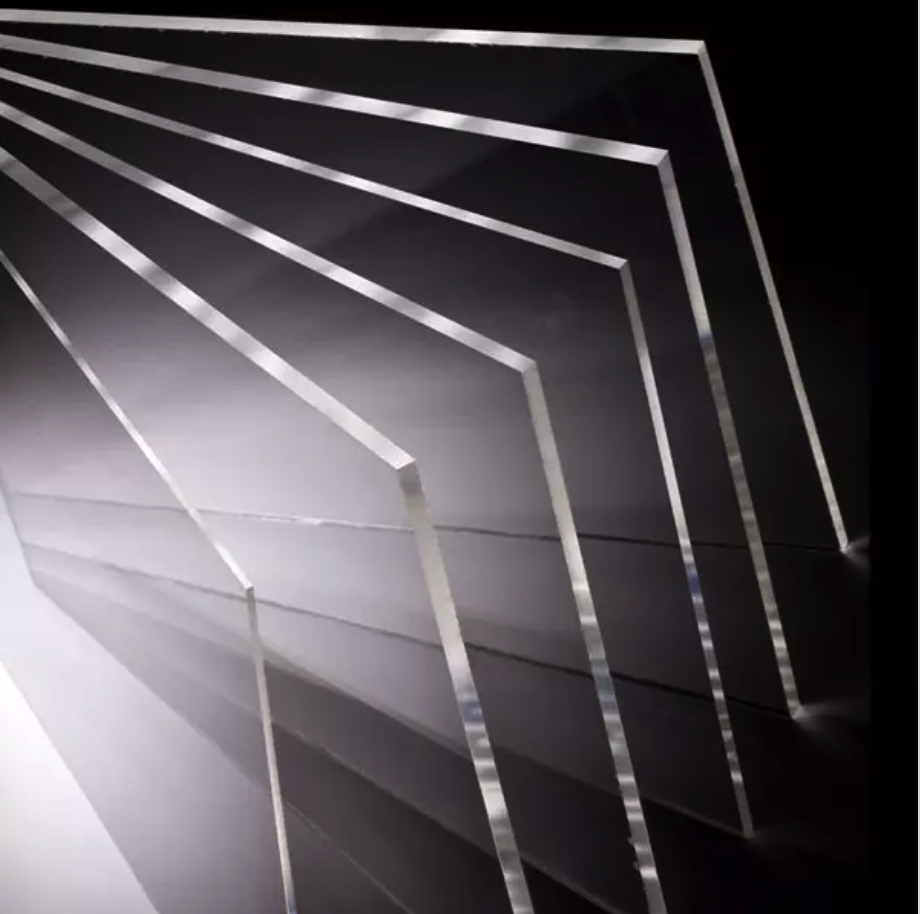

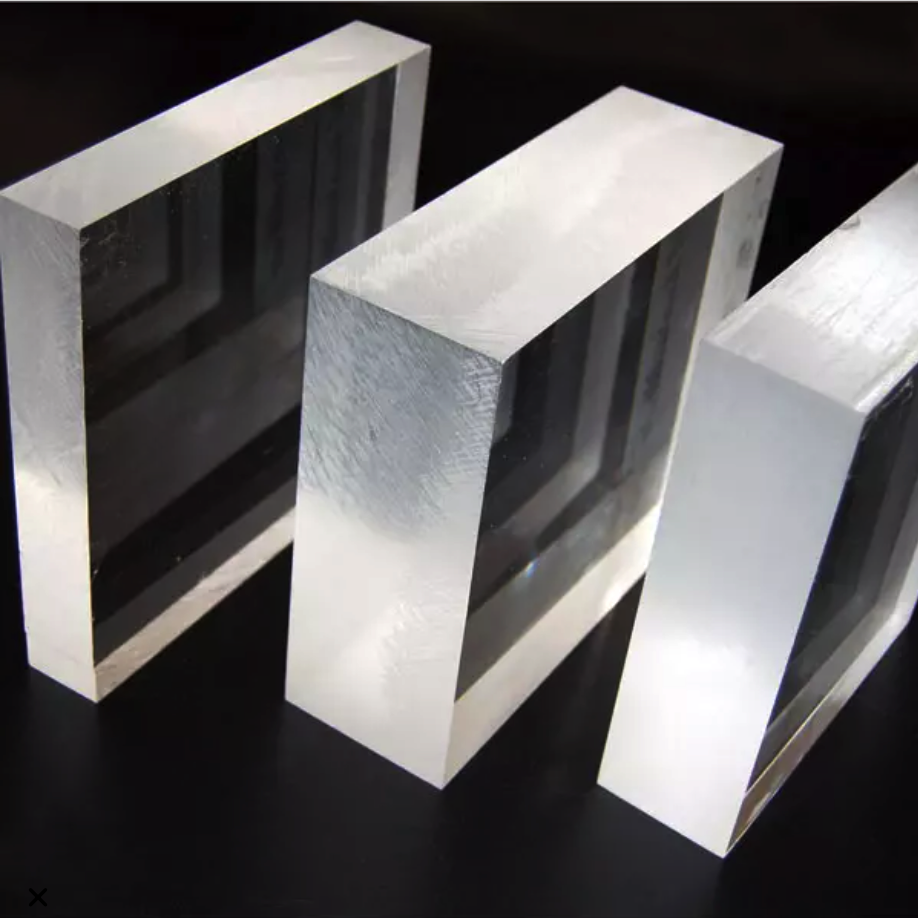

1.Cast acrylic sheet

2.Extruded acrylic sheet

3.Acrylic sheet for aquarium

4.Colored acrylic sheet

5.Glitter acrylic sheet

6.Textured acrylic sheet

7.Opaque acrylic sheet

8.Flexible acrylic sheet

9.Acrylic sheet cut to size

Acrylic is an important plastic polymer material developed earlier. It has good transparency, chemical stability and weather resistance, easy dyeing, easy processing, and a beautiful appearance. It is widely used in the construction industry. Plexiglass products can generally be divided into cast sheets, extruded sheets, and molding compounds.

What is Acrylic Sheet used for?

Casting type: The performance of the casting type sheet is better than that of the extrusion type, and the price is also more expensive. The casting type sheet is mainly used for carving, decoration, and handicraft production.

Extruded type: Extruded type is usually used for advertising signs, light boxes, etc.

Other uses of acrylic: it is used in various industries such as aircraft doors, tank lookouts, and the production of bathtubs.

Custom Cut Acrylic Sheet Fabrication

A. Casting plate - This technology uses MMA as raw material. Under the action of the initiator, heating and polymerization are performed. When the conversion rate reaches 10%, it is cooled to room temperature. After degassing, it is poured into a template made of inorganic glass. After water bath and drying The room is heated, and after the material is completely polymerized, it is released, and the acrylic sheet is covered with film and packaged to form the finished product. The template that leaves is being re-typed and recycled.

B. Development trend of the extruded board - The extruded board is suitable for single variety and mass production, and has high requirements for workers, but the length of the produced board can be adjusted, and long-width boards can be produced; the casting board process is simple, and the investment can be large or small. Flexible production, many product styles, and good surface finish, especially in small batches, special colors, and special thicknesses, have been widely developed.

Acrylic Sheets Characteristics and Benefits

Extruded Sheet

Compared with the cast sheet, the extruded sheet has a lower molecular weight, slightly weaker mechanical properties, and higher flexibility. However, this feature facilitates bending and thermoforming processes with a shorter softening time. It is beneficial for all kinds of rapid vacuum forming when dealing with larger size sheets. At the same time, the thickness tolerance of the extruded sheet is smaller than that of the cast sheet. Due to the large-scale automatic production of extruded sheets, the color and specifications are inconvenient to adjust, so the variety of product specifications is limited to a certain extent.

Cast Sheet

High molecular weight, excellent stiffness, strength, and excellent chemical resistance. Therefore, it is more suitable for processing large-sized logo plaques, and the time is slightly longer than that in the softening process. This kind of board is characterized by small batch processing, unparalleled flexibility in the color system and surface texture effect, and complete product specifications, suitable for various special purposes.

Acrylic sheets will fit the requirements for a multitude of applications. Acrylic sheets are not harmful to human health or the environment in manufacturing, applications, or disposal. The acrylic sheet is free of lead, cadmium, and barium. All Acrylic Sheet products comply with national and international regulations relating to the environment.

Applications

In our daily life, it is widely used. For example, it can be used as an advertising facility, as a lightbox, or some signboards, display stands, etc.

In terms of transportation facilities, it is also widely used in trains or cars, and can be made into car lights.

In addition, the baby's incubator is made of acrylic, which maintains high transparency. At the same time, some medical appliances can also be made of materials.

In our daily life, telephone booths or shop windows, as well as integrated ceilings, screens, etc., can be made of acrylic sheets.

Share